Spot Welding JPC 35,50,75

Advantage:

- Good working performance through thyristor controller circuit eliminating contractors.Long Serviceable life.

- Power saving through usage of high quality conductive material and superior secondary circuit.

- Efficient after cooling circuit.

- Lower exhaust noise through unique construction.

- Safe usage through high insulation technique.

STUD WELDING WSN-2000II,WCD 1500,WTR 1500II

Stud welding is a form of spot welding where bolt or specially formed nuts is welded onto another metal part.The bolts maybe automatically fed into the spot welder.Weld nuts generally have a flange with a small nuts that melt to form the weld.Studs have a necked down,un-threaded area for the same purpose.Weld stud are used in stud welding system.

SUBMERGE ARC SAW1250DC

Typical Usage: oil &gas industry,pipe welding,ship building ,heavy fabrication,rail road,pressure vessel,fabrication.

Standard Accessories: Wire feed roller 3-4mm,wire feed roller 4.2-5mm,contact tip 3.2mm,contact tip 4.0mm,95 mm welding cable.

Standard Accessories: Wire feed roller 3-4mm,wire feed roller 4.2-5mm,contact tip 3.2mm,contact tip 4.0mm,95 mm welding cable.

DIESEL ENGINE ALPHAWELD 500D

the most rugged and reliable welding machine that we had ever build for heavy industrial use. Every component in this machine is engineered and built to ensure ultimate reliability in the most punishing condition.Engine drive is considered the best heavy duty machine all round and its generator fuel consumption is lower compare to other conventional source.

Automation -CNC cutting system

Provide welding automation solution towards customer needs and dedicated to solve production problem by:

- reduce production down time.

- to save operating cost.

- to increase production efficiency.

- to maintain product quality.

Multi guns spot example

Provide welding automation solution towards customer needs and dedicated to solve production problem by:

?1490276199)

- reduce production down time.

- to save operating cost.

- to increase production efficiency.

- to maintain product quality.

?1490276199)

KUKA robotic system

Benefits:

- faster welding cycle times

- no breaks in production

- better welding quality

- less wasted material

- remove workers from hazardous working environments

- more precision and flexibility to reach for hard-to-hard spots.

- saving money through speed,quality production and labor cost.

My Arc Pro 350 A Package

KR5 ARC ROBOT +350 A PRO POWER SOURCE + WIRE FEEDER + MY ARC 350T Air cooled Torch

CNC PLASMA CUTTING MACHINE

Benefits:

- faster cutting speed

- precision cut

- high cutting quality

- easy to use

- safe to use

CUTTING SYSTEM COMPONENTS

1)power source option

2)software

3)controller option

4)oxy cutting torch

2)software

3)controller option

4)oxy cutting torch

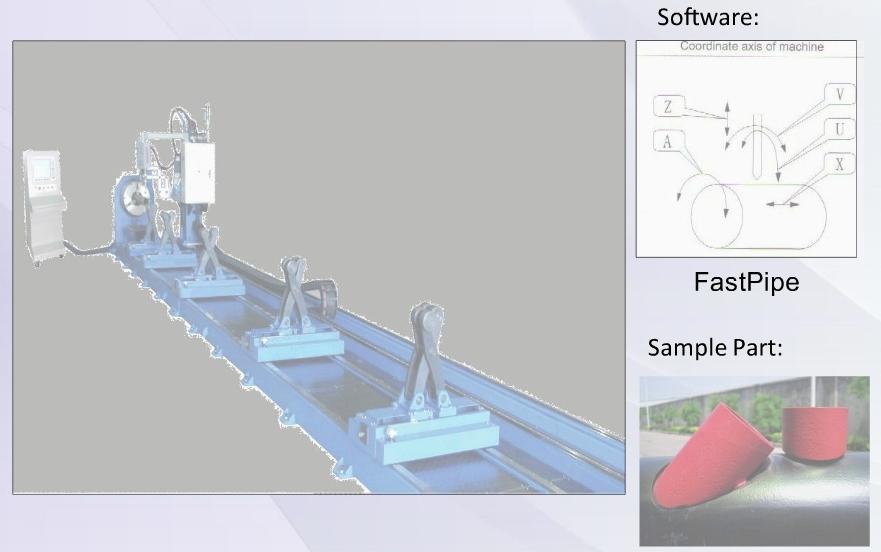

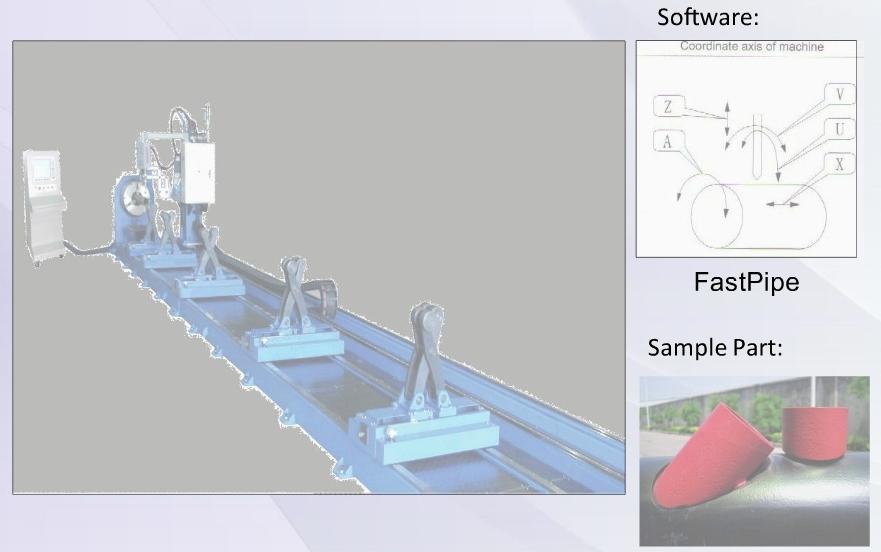

CNC PIPE CUTTING MACHINE

refer to the image

WELDING MANIPULATOR SYSTEM

Benefits:

- able to achieve consistent weld results

- able to maintain weld head over weld joint

- in a stable position during weld

- increase arc-on time and overall productivity.

- provides ability to have multi weld station using only one weld head,increasing your return on investment.

- reduce operator fatigue

- reduce consumable cost